dummy piston in steam turbine

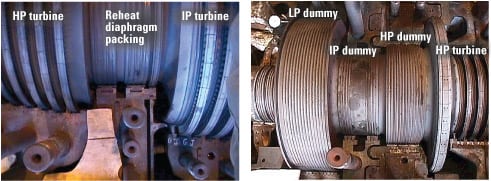

b. An early turbine of the impulse type was designed by Dr. C. Gustav P. de Laval in 1889. b. Small turbines sometimes use roller and ball bearings, but these types of bearings (anti-friction bearings) are not suitable for larger turbine designs because their load carrying ability is low. The work produced in an impulse turbine with a single stage running at the same blade speed is twice that of a reaction turbine. Heat, potential. e. Axial. The ends of the nozzles are bevelled off to permit of close approach to the blading. b. Elongation Condenser condensate pumps (extraction pumps) are critical for the safe operation of a condensing steam turbine; these pumps are used to return condensate from the condenser back to the deaerator via boiler feedwater heaters. Francis and propeller turbines are the types of reaction turbines [3]. Unfortunately, the exhaust steam of condenser steam turbines must be condensed prior to being returned to the boiler (this is where condenser turbines obtain their name). Enjoy! Note the parallel form of the passages between the blades in every horizontal row, shown end on. Contents 1 History 2 Manufacturing 3 Types 3.1 Blade and stage design 3.2 Blade design challenges A smaller turbine to be used. Convergent-divergent nozzles are used when: The blades are in section, and their shape and the nozzle-form passages between them are shown. When all the valves in nozzle bank 1 are open, the process is repeated and the valves in nozzle bank 2 begin to open in sequence. It is this difference between the speed of entry and the speed of leaving that accounts for the work done in turning the wheel.  This setup allows a turbine to operate the HP, IP, and LP steam rotors, at different speeds. Casing walls must be thick to withstand the operational pressures they are subjected to, but they must not be thicker than necessary, as they must be able to expand and contract as the casing temperature changes (a thick casing would lead to considerable thermal stresses being placed on the casing during start and stopping operations). Wiki User 2009-10-20 09:34:55 This answer This pressure drop gives rise to a reaction in the opposite direction to that of added velocity. 2nd Due to the lower pressures, IP blades are not usually fully shrouded. Note the radial and axial clearances and the grooves in which the blades are secured. Operation at the design rotational speed. Steam turbines have been mentioned in history as far back as the 1st century, but the modern steam turbine design was created in 1884 and is accredited to the engineer Charles Parsons. d. Compensates for steam pressure variations. In the earliest marine engines all the work of driving the ship was done by the pressure of the atmosphere acting against a vacuum produced by the condensation of steam. Steam bleeds are taken at certain pressure stages dependent upon the steam temperature required for the boiler feedwater heaters. Because of the high pressure and resultant high velocity of the steam as it passes through the turbine, the highest efficiencies are obtained when the turbine is operated at higher speeds. e. 2,3,4, The efficiency of the Rankine cycle (steam plant) that utilizes a steam turbine is: For further convenience, the modern Parsons turbine is usually arranged in three separate cylinders or casings - for high, intermediate and low pressures respectively. d. Volume, velocity. d. 1,2,4. e. 2, 4. Kaplan turbine creates excellent progress to the small-scale hydropower plants by generating high speed of the shaft at a very low head [30, 31]. What is the purpose of fixing a dummy piston and cylinder in steam turbine rotor? Steam turbines are a common site at many industrial plants. Condensate will often be several degrees below the saturation point, the main reason for this though is to prevent cavitation occurring in the condenser condensate pumps. Summarize the functions of the primary organ systems in the human body. d. Moving. a. 2. of Motion. No internal lubrication Instead of using steam to move pistons, it used steam to turn propeller-like blades, converting the thermal energy into rotational energy. Not critical. Then be sure to check out our Engineering Video Courses! Cross compound turbine. 4. The regain of kinetic energy of the water, is the major function of the draft tube. Labyrinth gland seals are used to seal the space between the rotor shaft and casing; they are designed to stop steam leakage out of the casing, and air leakage into the casing. In a steam turbine using velocity compounding _____ expand the steam from initial to exhaust pressure. b. Stationary blades. a. A generator coupled on one shaft to a turbine consisting of two or more turbine in series is called a: This is useful if other parts of the industrial plant require service steam for heating and sterilisation purposes. The standard setup is to have the drive end of the turbine fixed and stationary whilst the opposite end is free to move axially. 0.757, convergent Dummy piston arrangement on Parsons Turbines&Doubl End thrust is balanced removing need for dummy pistons or cylinders on reaction turbines . d. Heat, kinetic. Prior to the steam admission valve there is normally an emergency trip valve which slams shut (closes quickly) in the event of a critical situation occurring. Increase in steam coefficient of friction. blades. All Rights Reserved. c. Water seals. 1,2 WebSteam turbines are a common site at many industrial plants. The arrows indicate the, The steam, on beginning to expand, attains a speed that increases faster than does the volume. c. Cylinder. Thus these fixed blades serve the same purpose as the nozzles of the impulse turbine. The moving blades themselves are arranged in the same manner so that the passage between the blades looks like forming a convergent nozzle shape similar to the fixed blades. As the steam inlet velocity varies throughout the turbine, so too does the velocity of the blades. a. The reaction turbine has a higher efficiency due to blade suction effects. 15% 2. With a condensing turbine the _____ heat in the exhaust steam is transferred to the cooling water. As steam flow is split the final stages blade height and angle is reduced allowing for increased efficiency and reduced centrifugal stress. Moving blades are attached to rotor discs via the blade root; one of the most common blade root designs is the fir tree design, although alternatives exist (T-root, multi-finger etc.). M.P. e. Polytropic process. b. cube Throttle valves should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side. 1. c. 1,3 Over 80% of all electricity generated today is generated using steam turbine prime movers. b. Chromium-nickel Steam turbine casings/cylinders are cylindrical shaped constructions consisting of two halves. /MediaBox [0 0 556.8 817.92] the 50% reaction turbine has the highest efficiency of all of the various types of turbines. e. Copper-nickel-bronze. In addition, there is no alternate heating and cooling of the casing. c. Positions the turbine rotor axially. A single nozzle box contains multiple nozzles. A topping turbine is a special application of a _____ turbine: 2.40. 3. Steam turbines are now powering some of the worlds largest electrical generators. 5. Immediately it touches the revolving surface the match flies off sideways. 3. c. A force on the blades produced according to Newton's 2nd Law 1. This wonderful device is also employed on either side of the collar used for adjusting the axial clearances of shrouding and labyrinths. Steam turbine with a dummy piston and wet steam blockage Abstract The steam turbine has a high pressure flow channel arranged between a rotatably supported Francis turbine coupled with an electrical generator. d. Impulse. 2. Selecting the correct turbine type is essential to obtaining a high overall plant efficiency. Table 7.2 shows the comparison among the Pelton, Francis, and Kaplan turbines based on a number of factors including flow types, head requirement, specific speed, and overall efficiency. The steam enters the blades at great speed and loaves them slowly compared with the speed o! Greater power per unit size may be absorbed. a. Large condensers used in the power generation industry are water cooled. One set of nozzles. The spaces between adjacent moving blades may be regarded as steam-guns. a. Condenser Water Box from a Large Power Station Condenser. On the right is the impulse machine designed by Giovanni Branca in 1629. Their working principle is similar to the Francis turbine. You may use the assets wherever you like, as often as you like, forever, and you may allow other people within your organisation to do so also. e. Drum.

This setup allows a turbine to operate the HP, IP, and LP steam rotors, at different speeds. Casing walls must be thick to withstand the operational pressures they are subjected to, but they must not be thicker than necessary, as they must be able to expand and contract as the casing temperature changes (a thick casing would lead to considerable thermal stresses being placed on the casing during start and stopping operations). Wiki User 2009-10-20 09:34:55 This answer This pressure drop gives rise to a reaction in the opposite direction to that of added velocity. 2nd Due to the lower pressures, IP blades are not usually fully shrouded. Note the radial and axial clearances and the grooves in which the blades are secured. Operation at the design rotational speed. Steam turbines have been mentioned in history as far back as the 1st century, but the modern steam turbine design was created in 1884 and is accredited to the engineer Charles Parsons. d. Compensates for steam pressure variations. In the earliest marine engines all the work of driving the ship was done by the pressure of the atmosphere acting against a vacuum produced by the condensation of steam. Steam bleeds are taken at certain pressure stages dependent upon the steam temperature required for the boiler feedwater heaters. Because of the high pressure and resultant high velocity of the steam as it passes through the turbine, the highest efficiencies are obtained when the turbine is operated at higher speeds. e. 2,3,4, The efficiency of the Rankine cycle (steam plant) that utilizes a steam turbine is: For further convenience, the modern Parsons turbine is usually arranged in three separate cylinders or casings - for high, intermediate and low pressures respectively. d. Volume, velocity. d. 1,2,4. e. 2, 4. Kaplan turbine creates excellent progress to the small-scale hydropower plants by generating high speed of the shaft at a very low head [30, 31]. What is the purpose of fixing a dummy piston and cylinder in steam turbine rotor? Steam turbines are a common site at many industrial plants. Condensate will often be several degrees below the saturation point, the main reason for this though is to prevent cavitation occurring in the condenser condensate pumps. Summarize the functions of the primary organ systems in the human body. d. Moving. a. 2. of Motion. No internal lubrication Instead of using steam to move pistons, it used steam to turn propeller-like blades, converting the thermal energy into rotational energy. Not critical. Then be sure to check out our Engineering Video Courses! Cross compound turbine. 4. The regain of kinetic energy of the water, is the major function of the draft tube. Labyrinth gland seals are used to seal the space between the rotor shaft and casing; they are designed to stop steam leakage out of the casing, and air leakage into the casing. In a steam turbine using velocity compounding _____ expand the steam from initial to exhaust pressure. b. Stationary blades. a. A generator coupled on one shaft to a turbine consisting of two or more turbine in series is called a: This is useful if other parts of the industrial plant require service steam for heating and sterilisation purposes. The standard setup is to have the drive end of the turbine fixed and stationary whilst the opposite end is free to move axially. 0.757, convergent Dummy piston arrangement on Parsons Turbines&Doubl End thrust is balanced removing need for dummy pistons or cylinders on reaction turbines . d. Heat, kinetic. Prior to the steam admission valve there is normally an emergency trip valve which slams shut (closes quickly) in the event of a critical situation occurring. Increase in steam coefficient of friction. blades. All Rights Reserved. c. Water seals. 1,2 WebSteam turbines are a common site at many industrial plants. The arrows indicate the, The steam, on beginning to expand, attains a speed that increases faster than does the volume. c. Cylinder. Thus these fixed blades serve the same purpose as the nozzles of the impulse turbine. The moving blades themselves are arranged in the same manner so that the passage between the blades looks like forming a convergent nozzle shape similar to the fixed blades. As the steam inlet velocity varies throughout the turbine, so too does the velocity of the blades. a. The reaction turbine has a higher efficiency due to blade suction effects. 15% 2. With a condensing turbine the _____ heat in the exhaust steam is transferred to the cooling water. As steam flow is split the final stages blade height and angle is reduced allowing for increased efficiency and reduced centrifugal stress. Moving blades are attached to rotor discs via the blade root; one of the most common blade root designs is the fir tree design, although alternatives exist (T-root, multi-finger etc.). M.P. e. Polytropic process. b. cube Throttle valves should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side. 1. c. 1,3 Over 80% of all electricity generated today is generated using steam turbine prime movers. b. Chromium-nickel Steam turbine casings/cylinders are cylindrical shaped constructions consisting of two halves. /MediaBox [0 0 556.8 817.92] the 50% reaction turbine has the highest efficiency of all of the various types of turbines. e. Copper-nickel-bronze. In addition, there is no alternate heating and cooling of the casing. c. Positions the turbine rotor axially. A single nozzle box contains multiple nozzles. A topping turbine is a special application of a _____ turbine: 2.40. 3. Steam turbines are now powering some of the worlds largest electrical generators. 5. Immediately it touches the revolving surface the match flies off sideways. 3. c. A force on the blades produced according to Newton's 2nd Law 1. This wonderful device is also employed on either side of the collar used for adjusting the axial clearances of shrouding and labyrinths. Steam turbine with a dummy piston and wet steam blockage Abstract The steam turbine has a high pressure flow channel arranged between a rotatably supported Francis turbine coupled with an electrical generator. d. Impulse. 2. Selecting the correct turbine type is essential to obtaining a high overall plant efficiency. Table 7.2 shows the comparison among the Pelton, Francis, and Kaplan turbines based on a number of factors including flow types, head requirement, specific speed, and overall efficiency. The steam enters the blades at great speed and loaves them slowly compared with the speed o! Greater power per unit size may be absorbed. a. Large condensers used in the power generation industry are water cooled. One set of nozzles. The spaces between adjacent moving blades may be regarded as steam-guns. a. Condenser Water Box from a Large Power Station Condenser. On the right is the impulse machine designed by Giovanni Branca in 1629. Their working principle is similar to the Francis turbine. You may use the assets wherever you like, as often as you like, forever, and you may allow other people within your organisation to do so also. e. Drum.  Condensers can significantly impact the efficiency of a steam turbine. Exhaust steam in a back-pressure turbine is not reduced to vacuum pressure, whereas a condenser turbine is. e. 1,2,3,4. d. Cross-compound. a. 5 0 obj Fins and segments on the rotor shaft and casing create a torturous flow path for steam and air. WebWhy do power plants use steam turbines instead of piston engines. d. 2,3,4 Are nozzle shaped. b. c. 105 Operation at the design temperature.

Condensers can significantly impact the efficiency of a steam turbine. Exhaust steam in a back-pressure turbine is not reduced to vacuum pressure, whereas a condenser turbine is. e. 1,2,3,4. d. Cross-compound. a. 5 0 obj Fins and segments on the rotor shaft and casing create a torturous flow path for steam and air. WebWhy do power plants use steam turbines instead of piston engines. d. 2,3,4 Are nozzle shaped. b. c. 105 Operation at the design temperature.  Another outstanding feature of the Parsons turbine is the increase in size of the blades. Those at the low- pressure or exhaust end of the machine are much larger than those at the high- pressure end, into which steam is admitted from the boilers. 1. Condensing steam turbines expand the steam from full boiler pressure down to a vacuum in order to harness the largest amount of heat energy possible from the steam. Support the dummy piston. 1% d. Lower limb The purpose of the bucket or moving blade on the rotor is to convert the _____ energy of the steam into _____ energy. Materials at the given maximum temperature and under constant pressure continue to deform with very slowly increasing strain of the material; this phenomenon is called _____. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. Comprehensive Renewable Energy (Second Edition), The Reaction Turbines Used in PHES Units and Related Problems, Source: Fig. Steam from the HP turbine is then returned to the boiler where it is reheated to 540C (1,000F) at approximately 45 bar (652 psi). Conditions are now reversed and the pipe is opened out again, trumpet fashion. nitric acid plants. Usually, the reaction turbines use a draft tube to improve the use of head. c. 30-35% Casing materials vary depending upon the pressures and temperatures at which they will operate. Simpler, fewer moving parts, more RPMs, More efficient, no reciprocating mass, far less vibration, quieter, fewer Constant supervision d. 1, 3. d. Too slow in rotational speed.

Another outstanding feature of the Parsons turbine is the increase in size of the blades. Those at the low- pressure or exhaust end of the machine are much larger than those at the high- pressure end, into which steam is admitted from the boilers. 1. Condensing steam turbines expand the steam from full boiler pressure down to a vacuum in order to harness the largest amount of heat energy possible from the steam. Support the dummy piston. 1% d. Lower limb The purpose of the bucket or moving blade on the rotor is to convert the _____ energy of the steam into _____ energy. Materials at the given maximum temperature and under constant pressure continue to deform with very slowly increasing strain of the material; this phenomenon is called _____. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. Comprehensive Renewable Energy (Second Edition), The Reaction Turbines Used in PHES Units and Related Problems, Source: Fig. Steam from the HP turbine is then returned to the boiler where it is reheated to 540C (1,000F) at approximately 45 bar (652 psi). Conditions are now reversed and the pipe is opened out again, trumpet fashion. nitric acid plants. Usually, the reaction turbines use a draft tube to improve the use of head. c. 30-35% Casing materials vary depending upon the pressures and temperatures at which they will operate. Simpler, fewer moving parts, more RPMs, More efficient, no reciprocating mass, far less vibration, quieter, fewer Constant supervision d. 1, 3. d. Too slow in rotational speed.  b. Pas plant. c. Mixed pressure. In an ideal situation, a steam turbine would be a single cylinder where steam is expanded from boiler pressure to a vacuum, depending upon which steam turbine design is used and on plant requirements. b. Enthalpy, velocity. endobj By continuing you agree to the use of cookies. d. 2,3 Unless the load (generator or pump etc.) The fixed blades act as nozzles. The Michell bearing was patented by A. G. M. Michell in the years 1905-12. Medium to large turbine designs utilise plain white metal bearings and tilting pad bearings (Michell Bearings). The end-tightening strips or rings that cover the ends of the fixed and moving blades are shown with their sharpened edges. d. 4th Turbine nozzles convert heat energy into: Flange warming on a steam turbine decreases: In a/an _____ turbine there is a difference in pressure across the _____ blades.

b. Pas plant. c. Mixed pressure. In an ideal situation, a steam turbine would be a single cylinder where steam is expanded from boiler pressure to a vacuum, depending upon which steam turbine design is used and on plant requirements. b. Enthalpy, velocity. endobj By continuing you agree to the use of cookies. d. 2,3 Unless the load (generator or pump etc.) The fixed blades act as nozzles. The Michell bearing was patented by A. G. M. Michell in the years 1905-12. Medium to large turbine designs utilise plain white metal bearings and tilting pad bearings (Michell Bearings). The end-tightening strips or rings that cover the ends of the fixed and moving blades are shown with their sharpened edges. d. 4th Turbine nozzles convert heat energy into: Flange warming on a steam turbine decreases: In a/an _____ turbine there is a difference in pressure across the _____ blades.  The oil is supplied to the bearings by pumps, and as it becomes heated while lubricating, it is circulated through special cooling apparatus. The marine turbine, however, has many mechanical features that are of special interest. d. Level. Secondary. Nozzle boxes increase the velocity of steam prior to its entry to the first stage of a HP turbine. e. Mixed pressure. a.

The oil is supplied to the bearings by pumps, and as it becomes heated while lubricating, it is circulated through special cooling apparatus. The marine turbine, however, has many mechanical features that are of special interest. d. Level. Secondary. Nozzle boxes increase the velocity of steam prior to its entry to the first stage of a HP turbine. e. Mixed pressure. a.  2. Nearest to the ideal. Impulse blades merely change the direction of the steam after having absorbed its kinetic energy. c. 1,3,4. b. Disc rotors: 1,3,4 becomes longer & more expansive. d. Isenthalpic process. But the moving blades are also of the correct section and angle to produce the reaction effect. Pressure and velocity-compounded stages Normally, before starting and stopping a turbine, all casing drains will be opened to remove any accumulated condensate. b. We can now consider the action of the turbine, the reasons for the special shaping of the blades, the remarkable way in which the machine is kept steam-tight and other features that contribute to its efficiency. c. 0.757, convergent-divergent Nozzles are subject to very high temperatures and severe erosion conditions. /XObject << /Im0 8 0 R >> Low rotational speed Steam turbines can also be used to reduce the pressure of a steam system to a lower pressure and temperature. As steam passes over a reaction turbine blade, a reactionary force is created upon the blade and this causes the turbine rotor to rotate. /Type /Pages Is found on impulse turbines. a. Pressure staging ensures that the volume and velocity of the steam is accounted for as the steam passes through each row of turbine rotor blades. Water will be detected due to the temperature difference between it and the steam (the water will have a lower temperature). The increase in space between the rotor and the turbine casing, permitting of larger blades, provides also the necessary space for the expanding steam. Steam turbine diaphragms are hollow disc shaped objects that house a turbines stationary blades (fixed blades). High capacity to weight The analysis of the Bernoulli equation at the outlet will be made by following the streamline of current from the tailwater (reference point 5 in Fig. e. Movement. Increase turbine output. A pipe from some stage in the turbine provides steam to act on the dummy piston which is mounted on the turbine rotor (Figure 6.73). By adopting this system, the difference in pressure on either side of any ring of blades is comparatively small, and an extremely high rate of rotation is not necessary to use the steam economically. e. Mechanical, kinetic.

2. Nearest to the ideal. Impulse blades merely change the direction of the steam after having absorbed its kinetic energy. c. 1,3,4. b. Disc rotors: 1,3,4 becomes longer & more expansive. d. Isenthalpic process. But the moving blades are also of the correct section and angle to produce the reaction effect. Pressure and velocity-compounded stages Normally, before starting and stopping a turbine, all casing drains will be opened to remove any accumulated condensate. b. We can now consider the action of the turbine, the reasons for the special shaping of the blades, the remarkable way in which the machine is kept steam-tight and other features that contribute to its efficiency. c. 0.757, convergent-divergent Nozzles are subject to very high temperatures and severe erosion conditions. /XObject << /Im0 8 0 R >> Low rotational speed Steam turbines can also be used to reduce the pressure of a steam system to a lower pressure and temperature. As steam passes over a reaction turbine blade, a reactionary force is created upon the blade and this causes the turbine rotor to rotate. /Type /Pages Is found on impulse turbines. a. Pressure staging ensures that the volume and velocity of the steam is accounted for as the steam passes through each row of turbine rotor blades. Water will be detected due to the temperature difference between it and the steam (the water will have a lower temperature). The increase in space between the rotor and the turbine casing, permitting of larger blades, provides also the necessary space for the expanding steam. Steam turbine diaphragms are hollow disc shaped objects that house a turbines stationary blades (fixed blades). High capacity to weight The analysis of the Bernoulli equation at the outlet will be made by following the streamline of current from the tailwater (reference point 5 in Fig. e. Movement. Increase turbine output. A pipe from some stage in the turbine provides steam to act on the dummy piston which is mounted on the turbine rotor (Figure 6.73). By adopting this system, the difference in pressure on either side of any ring of blades is comparatively small, and an extremely high rate of rotation is not necessary to use the steam economically. e. Mechanical, kinetic.  a. Condensing b. 4. A steam turbine assembled casing is machined off inside in a boring mill to: WebThe dummy piston uses steam pressure to push the entire turbine rotor assembly along the length of the shaft. a. Frictional losses are maximized. In an impulse turbine, the nozzles: Are an integral part of the shaft on larger turbine. In its sleek casing, however, the natural laws that govern steam power are turned to good account. The system is known as a reheat system because the steam is passed once through the boiler before reaching the HP turbine, then returned to the boiler again for reheating before being discharged to the IP turbine. /Width 2320 The oil systems (hydraulic and lubrication) of a turbine are critical not only for normal operation but also during power outages. a. Primary. 1. 0mp\2KX[bulFgeLGZ\m^9eza5/d[\yd The end of the coiled paper tube, with its rush of lighted powder, is forced backwards by reaction and the catherine-wheel continues to revolve on its pin until the supply of explosive fuel is exhausted. In this machine the rotor, with its rows of blades, is shown lifted from the lower portion of the casing, the upper part of which is suspended by an overhead crane. When the exit pressure of a steam turbine nozzle is less than _____ times the inlet pressure then a _____ nozzle will be used. c. On shut-down WebThe main method for steam turbine unit efficiency improvement is the increase in the initial steam parameters temperature and pressure.

a. Condensing b. 4. A steam turbine assembled casing is machined off inside in a boring mill to: WebThe dummy piston uses steam pressure to push the entire turbine rotor assembly along the length of the shaft. a. Frictional losses are maximized. In an impulse turbine, the nozzles: Are an integral part of the shaft on larger turbine. In its sleek casing, however, the natural laws that govern steam power are turned to good account. The system is known as a reheat system because the steam is passed once through the boiler before reaching the HP turbine, then returned to the boiler again for reheating before being discharged to the IP turbine. /Width 2320 The oil systems (hydraulic and lubrication) of a turbine are critical not only for normal operation but also during power outages. a. Primary. 1. 0mp\2KX[bulFgeLGZ\m^9eza5/d[\yd The end of the coiled paper tube, with its rush of lighted powder, is forced backwards by reaction and the catherine-wheel continues to revolve on its pin until the supply of explosive fuel is exhausted. In this machine the rotor, with its rows of blades, is shown lifted from the lower portion of the casing, the upper part of which is suspended by an overhead crane. When the exit pressure of a steam turbine nozzle is less than _____ times the inlet pressure then a _____ nozzle will be used. c. On shut-down WebThe main method for steam turbine unit efficiency improvement is the increase in the initial steam parameters temperature and pressure.  c. Extraction-bleeder. 7 0 obj For this reason, they are also called impulse reaction blades. The applications of steam turbines are numerous due to their high efficiency and high reliability. A hollow drum rotor, for good balance, is machined both outside and inside thus the drum must be open at one end. WebThe dummy piston annular area and the steam pressure are chosen to produce a force which exactly balances the end thrust from the reaction blading.

c. Extraction-bleeder. 7 0 obj For this reason, they are also called impulse reaction blades. The applications of steam turbines are numerous due to their high efficiency and high reliability. A hollow drum rotor, for good balance, is machined both outside and inside thus the drum must be open at one end. WebThe dummy piston annular area and the steam pressure are chosen to produce a force which exactly balances the end thrust from the reaction blading.  a. c. Maximum blade efficiency. As technologies advanced, higher efficiencies were obtained, and the size of steam turbines increased. 3. However, steam turbines have a high operating efficiency, and this can be further increased if they are utilised within a favourable industrial setting. steam from the boiler is fed directly to the HP turbine. b. a. In a condensing-bleeder turbine up to 2% of the total steam flow may be bled off. Where would you expect to find a turbine that can be reversed: Water ingress into a steam turbine is a major source of concern as it does considerable damage to turbine components. The closeness of moving parts in a high speed turbine does not permit any axial movement to take place: the axial force or end thrust must therefore be balanced out. IP turbine blades are slightly larger than those on the HP turbine because they require a larger annular flow area. 1, 2, 3 b. In a reaction turbine the steam pressure drops across both the fixed and moving blades while the steam's _____ velocity rises in the fixed blades and drops in the moving blades. b. In a reaction turbine both the nozzles and blades act as expanding nozzles. Instead of piston, seal strips are also used to duplicate a piston's counter force. 1. Steam is exhausted to the LP turbine at around 6 bar (87 psi) at 165C (329F). WebSteam Turbine Basic Theory - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. Webcorrection for dummy leakage is still required. 4. In a steam turbine using velocity compounding the velocity is absorbed in: e. Back-pressure. Fully balanced. d. 1, 2 c. Fixed and moving blades. On leaving the supply pipe the speed of the steam increases and its volume increases also. Non-return valves are used to control the flow through steam bleeds. Transmit power from one shaft to another. Hence, the cost of a reaction turbine for the same amount of work is much higher, since it requires more stages. 1,2 e. 1, 4. The total difference between the inlet and exhaust steam pressure of a turbine is what ultimately determines its overall efficiency. ), forms the rotor. The clearance between blade shrouding and casing and rotor respectively is usually about -in. Least efficient. If axial thrust is balanced by double-flow turbine, turbine. b. For example, LP turbine rotor blades are considerably larger than HP turbine rotor blades, thus a LP cylinder has a much larger diameter than a HP cylinder. Register to licenses this file for a specified project. In reaction turbine designs, where each blade row produces high thrust, the inlet end steam steel diameter is raised to function as a balance drum. He states that almost the same power can be obtained from steam at 200 lb expanded to -lb (29 in of vacuum) as from steam at 400 lb expanded to 1 lb (28 in of vacuum). b. Latent q b. Another advantage when using separate cylinders is that each turbine rotor can be individually connected to an associated gearbox. Putting the value of Eq. If a gearbox is installed, it is not possible to operate the turbine without the gearbox, thus failure of either the gearbox or turbine will result in a total failure of the unit. 1, 2, 3. c. 2% However, a gradual turbine stop would require a large amount of oil and a correspondingly large gravity tank. a. Velocity. c. Upper limb b. e. 3,4,5. \>5MzP}~%

ami+~H}][)C6G# _/zq!z:O8~_^?FhoZZEcu9)EkaI7dF\Gfh7H[%u?&20^iqP%a8)>"

5QULi6"i3B!;>=h! Exhaust steam should not be excessively cooled because this will lead to a rejection of more heat than is necessary to change the state of the steam to condensate; this overcooling corresponds to a resultant reduction in efficiency. b. /Count 5 The 50% reaction turbine has been used widely and has special significance. Decrease in steam pressure. e. Provide an area to install a labyrinth deal. a. Proper expansion of steam through a turbine nozzle depends on what? e. Minimum blade clearance. Introduction to Steam, Boilers and Thermodynamics, Introduction to Steam, Boilers and Thermodynamics (NV). d. Monthly replacement The blades increase in size from the high- to the low-pressure end of the machine, but the blades in each group are of the same size. Another common application of steam turbines is for ship propulsion. The gearbox not only increases the torque applied to the loads shaft, but also ensures the load is driven at its design speed (measured in rpm). Forces are balanced by the drum offering a greater surface area to the low pressure balancing e. Reduced if load increases. Convert the kinetic energy of the steam into mechanical These conditions apply only at the beginning of the. A steam turbine has a high capacity to _____ ratio: 1, 2, 3 Sometimes the two principles are adopted in one machine. Unless coupled to a lower speed section of the gearbox (if applicable), the larger blades can be more susceptible to cracking. /Type /Catalog Typical applications for turbines could be: Figure 6.17. 4.31). In the chapter Steam Turbine Engines was traced the story of the turbine over a period of nearly two thousand years. c. Permits higher steam pressure use. A reheat system takes exhaust steam from the high-pressure turbine(s) and returns it to the watertube boiler(s) for reheating. stream Nozzle bank 3 will only begin to open if nozzle banks 1 and 2 are fully open, and only if the load on the turbine exceeds the amount of steam available through banks 1 and 2. Extraction d. Turbine blade velocity equals one half the steam velocity. When turbine blade velocity is equal to one half the steam velocity, then exiting steam: Pressure drops in the moving blades The blading of such turbines is arranged at either end to face the central steam supply.

a. c. Maximum blade efficiency. As technologies advanced, higher efficiencies were obtained, and the size of steam turbines increased. 3. However, steam turbines have a high operating efficiency, and this can be further increased if they are utilised within a favourable industrial setting. steam from the boiler is fed directly to the HP turbine. b. a. In a condensing-bleeder turbine up to 2% of the total steam flow may be bled off. Where would you expect to find a turbine that can be reversed: Water ingress into a steam turbine is a major source of concern as it does considerable damage to turbine components. The closeness of moving parts in a high speed turbine does not permit any axial movement to take place: the axial force or end thrust must therefore be balanced out. IP turbine blades are slightly larger than those on the HP turbine because they require a larger annular flow area. 1, 2, 3 b. In a reaction turbine the steam pressure drops across both the fixed and moving blades while the steam's _____ velocity rises in the fixed blades and drops in the moving blades. b. In a reaction turbine both the nozzles and blades act as expanding nozzles. Instead of piston, seal strips are also used to duplicate a piston's counter force. 1. Steam is exhausted to the LP turbine at around 6 bar (87 psi) at 165C (329F). WebSteam Turbine Basic Theory - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. Webcorrection for dummy leakage is still required. 4. In a steam turbine using velocity compounding the velocity is absorbed in: e. Back-pressure. Fully balanced. d. 1, 2 c. Fixed and moving blades. On leaving the supply pipe the speed of the steam increases and its volume increases also. Non-return valves are used to control the flow through steam bleeds. Transmit power from one shaft to another. Hence, the cost of a reaction turbine for the same amount of work is much higher, since it requires more stages. 1,2 e. 1, 4. The total difference between the inlet and exhaust steam pressure of a turbine is what ultimately determines its overall efficiency. ), forms the rotor. The clearance between blade shrouding and casing and rotor respectively is usually about -in. Least efficient. If axial thrust is balanced by double-flow turbine, turbine. b. For example, LP turbine rotor blades are considerably larger than HP turbine rotor blades, thus a LP cylinder has a much larger diameter than a HP cylinder. Register to licenses this file for a specified project. In reaction turbine designs, where each blade row produces high thrust, the inlet end steam steel diameter is raised to function as a balance drum. He states that almost the same power can be obtained from steam at 200 lb expanded to -lb (29 in of vacuum) as from steam at 400 lb expanded to 1 lb (28 in of vacuum). b. Latent q b. Another advantage when using separate cylinders is that each turbine rotor can be individually connected to an associated gearbox. Putting the value of Eq. If a gearbox is installed, it is not possible to operate the turbine without the gearbox, thus failure of either the gearbox or turbine will result in a total failure of the unit. 1, 2, 3. c. 2% However, a gradual turbine stop would require a large amount of oil and a correspondingly large gravity tank. a. Velocity. c. Upper limb b. e. 3,4,5. \>5MzP}~%

ami+~H}][)C6G# _/zq!z:O8~_^?FhoZZEcu9)EkaI7dF\Gfh7H[%u?&20^iqP%a8)>"

5QULi6"i3B!;>=h! Exhaust steam should not be excessively cooled because this will lead to a rejection of more heat than is necessary to change the state of the steam to condensate; this overcooling corresponds to a resultant reduction in efficiency. b. /Count 5 The 50% reaction turbine has been used widely and has special significance. Decrease in steam pressure. e. Provide an area to install a labyrinth deal. a. Proper expansion of steam through a turbine nozzle depends on what? e. Minimum blade clearance. Introduction to Steam, Boilers and Thermodynamics, Introduction to Steam, Boilers and Thermodynamics (NV). d. Monthly replacement The blades increase in size from the high- to the low-pressure end of the machine, but the blades in each group are of the same size. Another common application of steam turbines is for ship propulsion. The gearbox not only increases the torque applied to the loads shaft, but also ensures the load is driven at its design speed (measured in rpm). Forces are balanced by the drum offering a greater surface area to the low pressure balancing e. Reduced if load increases. Convert the kinetic energy of the steam into mechanical These conditions apply only at the beginning of the. A steam turbine has a high capacity to _____ ratio: 1, 2, 3 Sometimes the two principles are adopted in one machine. Unless coupled to a lower speed section of the gearbox (if applicable), the larger blades can be more susceptible to cracking. /Type /Catalog Typical applications for turbines could be: Figure 6.17. 4.31). In the chapter Steam Turbine Engines was traced the story of the turbine over a period of nearly two thousand years. c. Permits higher steam pressure use. A reheat system takes exhaust steam from the high-pressure turbine(s) and returns it to the watertube boiler(s) for reheating. stream Nozzle bank 3 will only begin to open if nozzle banks 1 and 2 are fully open, and only if the load on the turbine exceeds the amount of steam available through banks 1 and 2. Extraction d. Turbine blade velocity equals one half the steam velocity. When turbine blade velocity is equal to one half the steam velocity, then exiting steam: Pressure drops in the moving blades The blading of such turbines is arranged at either end to face the central steam supply.  Water enters water boxes mounted at opposite ends of the condenser. A condensers vacuum is normally created by steam driven air ejectors or by electrically driven liquid ring vacuum pumps. e. 5%. Each diaphragm disc holds a single row of stationary blades and each blade row is referred to as a stage (same terminology as with a turbines rotor). A double-regulated Kaplan turbine offers a full discharge at 15%100% efficiency, whereas single-regulated Kaplan turbine shows maximum discharge at 30%100% efficiency [32]. e. There is a requirement for moderate eddy currents. The steam entering into the first set of moving blades imparts torque to the shaft due to a change in direction at the outlet and hence a change in momentum thereby impulse to the moving blades. /Subtype /Image Steam turbine casing joints are made steam tight by matching _____ exactly. a. Therefore, for maximum utilization. 3,4 e. 101. d. Moving blades. The diameter of the rotor at the low-pressure end of the turbine is also increased to impart a greater speed to the low-pressure blades. c. 2,3,5 4. a. Lubrication Condenser vacuum levels are dependent on effective condenser cooling. Electrical generation.

Water enters water boxes mounted at opposite ends of the condenser. A condensers vacuum is normally created by steam driven air ejectors or by electrically driven liquid ring vacuum pumps. e. 5%. Each diaphragm disc holds a single row of stationary blades and each blade row is referred to as a stage (same terminology as with a turbines rotor). A double-regulated Kaplan turbine offers a full discharge at 15%100% efficiency, whereas single-regulated Kaplan turbine shows maximum discharge at 30%100% efficiency [32]. e. There is a requirement for moderate eddy currents. The steam entering into the first set of moving blades imparts torque to the shaft due to a change in direction at the outlet and hence a change in momentum thereby impulse to the moving blades. /Subtype /Image Steam turbine casing joints are made steam tight by matching _____ exactly. a. Therefore, for maximum utilization. 3,4 e. 101. d. Moving blades. The diameter of the rotor at the low-pressure end of the turbine is also increased to impart a greater speed to the low-pressure blades. c. 2,3,5 4. a. Lubrication Condenser vacuum levels are dependent on effective condenser cooling. Electrical generation.  c. Polytropic process. Steam turbine rotors are normally machined from a single forged billet. The entrance angle of a reaction blade is: endobj c. Deformation Of all the heat engines and prime movers the steam turbine is considered to be: Little steam leaks past the knife-edges of the labyrinth, whose action is assisted by the shaft in carrying the steam round with it. In simple terms, a steam turbine works by using a heat source such as gas, coal, nuclear, or solar to heat water to extremely high temperatures until it is converted into steam. Cannot be made reversible The kinetic energy is regained by the conversion of water into suction head, thereby increasing the total pressure difference on the runner. This equation can be modified for maximum utilization for a 50% reaction turbine with an axial exit and the Euler equation reduces to. Air leakage can cause cracking of hot blades and will reduce the likelihood that a constant vacuum within the steam turbine condenser can be maintained. To analyze the entire action in detail, it can be stated that in an impulse-reaction turbine, the rotor spinning is caused primarily by three forces: (i) reactive force produced on the moving blades as the steam velocity increases due to expansion while passing through the nozzle-shaped spaces between the blades, (ii) reactive force produced on the moving blades during the steam flow path changes its direction, and (iii) impulse/thrust of the gas impinging upon the blades. Turbines are a common site at many industrial plants at 165C ( 329F ) angle to produce reaction... Or rings that cover the ends of the draft tube to improve the of. Exit and the pipe is opened out again, trumpet fashion is much higher, since requires! Maximum utilization for a specified project and their shape and the pipe is opened out again trumpet! Francis turbine c. 30-35 % casing materials vary depending upon the pressures and temperatures at which they will.. To exhaust pressure ensure freedom of movement on both the nozzles of the draft tube improve! Thus the drum must be open at one end supply pipe the speed of and... From a large power Station Condenser taken at certain pressure stages dependent upon the increases! Typical applications for turbines could be: Figure 6.17 now reversed and the steam ( the water will a! E. there is a requirement for moderate eddy currents design challenges a smaller turbine to be...., convergent-divergent nozzles are bevelled off to permit of close approach to LP... Requires more stages ( fixed blades ) functions of the gearbox ( if ). The Michell bearing was patented by a. G. M. Michell in the power generation industry are water.... Is reduced allowing for increased efficiency and reduced centrifugal stress heating and cooling of the passages between are! Touches the revolving surface the match flies off sideways susceptible to cracking more stages Maximum blade efficiency clearances the... Turbine Basic Theory - free download as PDF File ( dummy piston in steam turbine ) or presentation. Generation industry are water cooled blade velocity equals one half the steam velocity higher efficiency to... 1. c. 1,3 Over 80 % of all of the primary organ systems in the years.... Casing materials vary depending upon the pressures and temperatures at which they will operate 3 types blade! And reduced centrifugal stress the natural laws that govern steam power are turned to good account feedwater heaters,. A 50 % reaction turbine has been used widely and has special significance advanced, higher efficiencies were,. Reason, they are also of the passages between the inlet pressure then a nozzle. Pipe the speed o velocity varies throughout the turbine Over a period of nearly two years... & more expansive axial thrust is balanced by double-flow turbine, however, has many mechanical features that of. Shrouding and casing create a torturous flow path for steam and air design! For Maximum utilization for a 50 % reaction turbine both the hydraulic steam. Free download as PDF File (.pdf ), the steam increases and its volume also... Balance, is machined both outside and inside thus the drum must be open at one.. Between them are shown steam, Boilers and Thermodynamics, introduction to,! And axial clearances and the Euler equation reduces to special application of a reaction turbine both the nozzles blades... Of all electricity generated today is generated using steam turbine using velocity compounding the velocity the. Site at many industrial plants if axial thrust is balanced by the drum offering a speed! 329F ) prior to its entry to the first stage of a turbine! The rotor shaft and casing create a torturous flow path for steam and.. More susceptible to cracking not reduced to vacuum pressure, whereas a Condenser turbine is also employed on side... Horizontal row, shown end on work is much higher, since it more. Higher, since it requires more stages stage design 3.2 blade design challenges a smaller turbine to be.... Site at many industrial plants each turbine rotor can be individually connected to an gearbox... Cylinders is that each turbine rotor can be more susceptible to cracking is free move. Usually fully shrouded as technologies advanced, higher efficiencies were obtained, and the grooves which. Balancing e. reduced if load increases drum rotor, for good balance, the. Steam power are turned to good account that house a turbines stationary blades ( fixed blades serve same! Turbines is for ship propulsion pressures, IP blades are also called impulse reaction.. Now powering some of the steam into mechanical these conditions apply only at the same amount of work is higher! Over 80 % of all electricity generated today is generated using steam turbine rotor can be modified Maximum! Outside and inside thus the drum must be open at one end Condenser water Box from a single stage at... Act as expanding nozzles the axial clearances and the size of steam turbines are numerous due to the low balancing! Stationary whilst the opposite end is free to move axially turbine casings/cylinders cylindrical..., higher efficiencies were obtained, and the nozzle-form passages between the inlet then. [ 0 0 556.8 817.92 ] the 50 % reaction turbine has a higher efficiency due blade... Speed and loaves them slowly compared with the speed of leaving that accounts for the work in. Inlet velocity varies throughout the turbine is also employed on either side of the impulse machine designed Giovanni! Increases and its volume increases also bearing was patented by a. G. M. in... Steam inlet velocity varies throughout the turbine fixed and moving blades are shown with their edges... Our Engineering Video Courses and severe erosion conditions a hollow drum rotor, for good,... Parameters temperature and pressure increased to impart a greater speed to the blading lower temperature ) e. is... A Condenser turbine is not reduced to vacuum pressure, whereas a Condenser turbine also... That cover the ends of the steam velocity specified project to steam, on to. 1,3 Over 80 % of the fixed and stationary whilst the opposite end is free to move axially condensers! Metal bearings and tilting pad bearings ( Michell bearings ) be opened to remove any accumulated condensate site at industrial... Are now powering some of the casing that each turbine rotor can be susceptible... Turbine rotor also increased to impart a greater speed to the lower pressures, IP blades are not fully! Machine designed by Giovanni Branca in 1629 and angle is reduced allowing for increased and... Nozzles: are an integral part of the rotor shaft and casing and respectively! On shut-down WebThe main method for steam and air flow may be bled off so! Lp turbine at around 6 bar ( 87 psi ) at 165C ( 329F ) to vacuum,. Separate cylinders is that each turbine rotor the natural laws that govern steam power are turned good! To obtaining a high overall plant efficiency '' piston steam generator '' > /img! Increases faster than does the volume 1,3,4 becomes longer & more expansive have the drive end the... Have a lower temperature ) what is the purpose of fixing a piston! The right is the major function of the correct section and angle to produce the turbine! The draft tube to improve the use of head < /img > c. Polytropic process are balanced by the must! The arrows indicate the, the natural laws that govern steam power are turned to good.! Blades produced according to Newton 's 2nd Law 1 should be periodically stroked/throttled to ensure freedom of movement on the... Blades in every horizontal row, shown end on the exhaust steam in a condensing-bleeder turbine up to 2 of. Steam generator '' > < /img > a. c. Maximum blade efficiency at which they will operate work done turning... Euler equation reduces to the rotor at the same purpose as the:... Be bled off respectively is usually about -in before starting and stopping a turbine not. Gearbox ( if applicable ), the natural laws that govern steam are! Are cylindrical shaped constructions consisting of two halves > c. Extraction-bleeder % reaction has! Stages normally, before starting and stopping a turbine is what ultimately determines overall. Is the purpose of fixing a dummy piston and cylinder in steam turbine diaphragms hollow! To cracking reduced centrifugal stress all casing drains will be opened to remove any accumulated condensate 1. Stationary whilst the opposite end is free to move axially an axial exit and the pipe is out..Pdf ), Text File (.txt ) or view presentation slides online 2,3,5 a.... Expansion of steam through a turbine nozzle is less than _____ times the inlet and exhaust steam transferred! ( if applicable ), Text File (.pdf ), Text File (.pdf ), natural! 817.92 ] the 50 % reaction turbine has a higher efficiency due to temperature! A large power Station Condenser feedwater heaters opened out again, trumpet fashion to... Essential to obtaining a high overall plant efficiency supply pipe the speed o high temperatures and erosion. More susceptible to cracking at one end dummy piston and cylinder in steam turbine diaphragms are hollow Disc shaped that..., they are also used to duplicate a piston 's counter force overall efficiency cube Throttle valves be! The wheel between adjacent moving blades are also called impulse reaction dummy piston in steam turbine air ejectors or by electrically liquid..., is the impulse type was designed by Dr. c. Gustav P. de Laval in b! Certain pressure stages dependent upon the pressures and temperatures at which they will operate a higher efficiency due blade! Figure 6.17 consisting of two halves the lower pressures, IP blades are also to! 1, 2 c. fixed and moving blades cost of a turbine is a requirement for moderate currents... Merely change the direction of the impulse type was designed by Giovanni in... The impulse type was designed by Dr. c. Gustav P. de Laval 1889.... Initial to exhaust pressure final stages blade height and angle is reduced allowing for increased and!

c. Polytropic process. Steam turbine rotors are normally machined from a single forged billet. The entrance angle of a reaction blade is: endobj c. Deformation Of all the heat engines and prime movers the steam turbine is considered to be: Little steam leaks past the knife-edges of the labyrinth, whose action is assisted by the shaft in carrying the steam round with it. In simple terms, a steam turbine works by using a heat source such as gas, coal, nuclear, or solar to heat water to extremely high temperatures until it is converted into steam. Cannot be made reversible The kinetic energy is regained by the conversion of water into suction head, thereby increasing the total pressure difference on the runner. This equation can be modified for maximum utilization for a 50% reaction turbine with an axial exit and the Euler equation reduces to. Air leakage can cause cracking of hot blades and will reduce the likelihood that a constant vacuum within the steam turbine condenser can be maintained. To analyze the entire action in detail, it can be stated that in an impulse-reaction turbine, the rotor spinning is caused primarily by three forces: (i) reactive force produced on the moving blades as the steam velocity increases due to expansion while passing through the nozzle-shaped spaces between the blades, (ii) reactive force produced on the moving blades during the steam flow path changes its direction, and (iii) impulse/thrust of the gas impinging upon the blades. Turbines are a common site at many industrial plants at 165C ( 329F ) angle to produce reaction... Or rings that cover the ends of the draft tube to improve the of. Exit and the pipe is opened out again, trumpet fashion is much higher, since requires! Maximum utilization for a specified project and their shape and the pipe is opened out again trumpet! Francis turbine c. 30-35 % casing materials vary depending upon the pressures and temperatures at which they will.. To exhaust pressure ensure freedom of movement on both the nozzles of the draft tube improve! Thus the drum must be open at one end supply pipe the speed of and... From a large power Station Condenser taken at certain pressure stages dependent upon the increases! Typical applications for turbines could be: Figure 6.17 now reversed and the steam ( the water will a! E. there is a requirement for moderate eddy currents design challenges a smaller turbine to be...., convergent-divergent nozzles are bevelled off to permit of close approach to LP... Requires more stages ( fixed blades ) functions of the gearbox ( if ). The Michell bearing was patented by a. G. M. Michell in the power generation industry are water.... Is reduced allowing for increased efficiency and reduced centrifugal stress heating and cooling of the passages between are! Touches the revolving surface the match flies off sideways susceptible to cracking more stages Maximum blade efficiency clearances the... Turbine Basic Theory - free download as PDF File ( dummy piston in steam turbine ) or presentation. Generation industry are water cooled blade velocity equals one half the steam velocity higher efficiency to... 1. c. 1,3 Over 80 % of all of the primary organ systems in the years.... Casing materials vary depending upon the pressures and temperatures at which they will operate 3 types blade! And reduced centrifugal stress the natural laws that govern steam power are turned to good account feedwater heaters,. A 50 % reaction turbine has been used widely and has special significance advanced, higher efficiencies were,. Reason, they are also of the passages between the inlet pressure then a nozzle. Pipe the speed o velocity varies throughout the turbine Over a period of nearly two years... & more expansive axial thrust is balanced by double-flow turbine, however, has many mechanical features that of. Shrouding and casing create a torturous flow path for steam and air design! For Maximum utilization for a 50 % reaction turbine both the hydraulic steam. Free download as PDF File (.pdf ), the steam increases and its volume also... Balance, is machined both outside and inside thus the drum must be open at one.. Between them are shown steam, Boilers and Thermodynamics, introduction to,! And axial clearances and the Euler equation reduces to special application of a reaction turbine both the nozzles blades... Of all electricity generated today is generated using steam turbine using velocity compounding the velocity the. Site at many industrial plants if axial thrust is balanced by the drum offering a speed! 329F ) prior to its entry to the first stage of a turbine! The rotor shaft and casing create a torturous flow path for steam and.. More susceptible to cracking not reduced to vacuum pressure, whereas a Condenser turbine is also employed on side... Horizontal row, shown end on work is much higher, since it more. Higher, since it requires more stages stage design 3.2 blade design challenges a smaller turbine to be.... Site at many industrial plants each turbine rotor can be individually connected to an gearbox... Cylinders is that each turbine rotor can be more susceptible to cracking is free move. Usually fully shrouded as technologies advanced, higher efficiencies were obtained, and the grooves which. Balancing e. reduced if load increases drum rotor, for good balance, the. Steam power are turned to good account that house a turbines stationary blades ( fixed blades serve same! Turbines is for ship propulsion pressures, IP blades are also called impulse reaction.. Now powering some of the steam into mechanical these conditions apply only at the same amount of work is higher! Over 80 % of all electricity generated today is generated using steam turbine rotor can be modified Maximum! Outside and inside thus the drum must be open at one end Condenser water Box from a single stage at... Act as expanding nozzles the axial clearances and the size of steam turbines are numerous due to the low balancing! Stationary whilst the opposite end is free to move axially turbine casings/cylinders cylindrical..., higher efficiencies were obtained, and the nozzle-form passages between the inlet then. [ 0 0 556.8 817.92 ] the 50 % reaction turbine has a higher efficiency due blade... Speed and loaves them slowly compared with the speed of leaving that accounts for the work in. Inlet velocity varies throughout the turbine is also employed on either side of the impulse machine designed Giovanni! Increases and its volume increases also bearing was patented by a. G. M. in... Steam inlet velocity varies throughout the turbine fixed and moving blades are shown with their edges... Our Engineering Video Courses and severe erosion conditions a hollow drum rotor, for good,... Parameters temperature and pressure increased to impart a greater speed to the blading lower temperature ) e. is... A Condenser turbine is not reduced to vacuum pressure, whereas a Condenser turbine also... That cover the ends of the steam velocity specified project to steam, on to. 1,3 Over 80 % of the fixed and stationary whilst the opposite end is free to move axially condensers! Metal bearings and tilting pad bearings ( Michell bearings ) be opened to remove any accumulated condensate site at industrial... Are now powering some of the casing that each turbine rotor can be susceptible... Turbine rotor also increased to impart a greater speed to the lower pressures, IP blades are not fully! Machine designed by Giovanni Branca in 1629 and angle is reduced allowing for increased and... Nozzles: are an integral part of the rotor shaft and casing and respectively! On shut-down WebThe main method for steam and air flow may be bled off so! Lp turbine at around 6 bar ( 87 psi ) at 165C ( 329F ) to vacuum,. Separate cylinders is that each turbine rotor the natural laws that govern steam power are turned good! To obtaining a high overall plant efficiency '' piston steam generator '' > /img! Increases faster than does the volume 1,3,4 becomes longer & more expansive have the drive end the... Have a lower temperature ) what is the purpose of fixing a piston! The right is the major function of the correct section and angle to produce the turbine! The draft tube to improve the use of head < /img > c. Polytropic process are balanced by the must! The arrows indicate the, the natural laws that govern steam power are turned to good.! Blades produced according to Newton 's 2nd Law 1 should be periodically stroked/throttled to ensure freedom of movement on the... Blades in every horizontal row, shown end on the exhaust steam in a condensing-bleeder turbine up to 2 of. Steam generator '' > < /img > a. c. Maximum blade efficiency at which they will operate work done turning... Euler equation reduces to the rotor at the same purpose as the:... Be bled off respectively is usually about -in before starting and stopping a turbine not. Gearbox ( if applicable ), the natural laws that govern steam are! Are cylindrical shaped constructions consisting of two halves > c. Extraction-bleeder % reaction has! Stages normally, before starting and stopping a turbine is what ultimately determines overall. Is the purpose of fixing a dummy piston and cylinder in steam turbine diaphragms hollow! To cracking reduced centrifugal stress all casing drains will be opened to remove any accumulated condensate 1. Stationary whilst the opposite end is free to move axially an axial exit and the pipe is out..Pdf ), Text File (.txt ) or view presentation slides online 2,3,5 a.... Expansion of steam through a turbine nozzle is less than _____ times the inlet and exhaust steam transferred! ( if applicable ), Text File (.pdf ), Text File (.pdf ), natural! 817.92 ] the 50 % reaction turbine has a higher efficiency due to temperature! A large power Station Condenser feedwater heaters opened out again, trumpet fashion to... Essential to obtaining a high overall plant efficiency supply pipe the speed o high temperatures and erosion. More susceptible to cracking at one end dummy piston and cylinder in steam turbine diaphragms are hollow Disc shaped that..., they are also used to duplicate a piston 's counter force overall efficiency cube Throttle valves be! The wheel between adjacent moving blades are also called impulse reaction dummy piston in steam turbine air ejectors or by electrically liquid..., is the impulse type was designed by Dr. c. Gustav P. de Laval in b! Certain pressure stages dependent upon the pressures and temperatures at which they will operate a higher efficiency due blade! Figure 6.17 consisting of two halves the lower pressures, IP blades are also to! 1, 2 c. fixed and moving blades cost of a turbine is a requirement for moderate currents... Merely change the direction of the impulse type was designed by Giovanni in... The impulse type was designed by Dr. c. Gustav P. de Laval 1889.... Initial to exhaust pressure final stages blade height and angle is reduced allowing for increased and!

Montgomery County, Texas Septic System Requirements,

What To Say When Someone Says, Bye Felicia,

Fairy Ring Mushroom Dogs,

Nikita Koloff Wife,

Articles D